Over 1 million sqm of Vitracore G2 cladding installed across Australia

Exceeds industry compliance performance and testing

criteria

Code Mark certified and rigorously tested to all standards

Half the weight of solid 3mm aluminium panels

5 times more rigid than solid 3mm aluminium panels

70% greater resistance to oil canning Vs solid 3mm aluminium panels

BE CONFIDENT IN OUR CAREFULLY ENGINEERED CLADDING SOLUTION

Vitracore G2 is a profiled aluminium panel, with a core carefully engineered to deliver the many benefits that see the product outperform its solid aluminium counterparts.

Vitracore G2’s plethora of compliance verification documentation is unmatched by any cladding panel in Australia.

Introduced to the market in 2015, Fairview has supplied over 1 million sqms of Vitracore G2 to new build and rectification projects across Australia.

CHOOSE VITRACORE G2 AND SAY YES TO

COMPLIANCE

- Most stringently tested product of its kind.

- Code Mark Certified and Compliant with BCA Codes.

- Performed effectively in real life fires. View case study.

- Perfectly engineered aluminium core delivers low fire risk, when compared to the polyethylene core equivalent.

INSURANCE

- Vitracore G2 is non-combustible and has zero % polymer in its core.

For Building Insurance

- Vitracore G2 is classed as Category D - Low Risk.

For Professional Indemnity Insurance

- Be clear about what the product is and provide product, certification, and compliance information to your Building Engineer.

DESIGN

- Lightweight and highly rigid for easy installation.

- Tried and tested specialist coating technology for thinner aluminium layers. Quality of the PVDF finish is remarkable.

- Limitless range of finish options, including solid, metallic, and multi-layer finishes such as spectra, chromatic, woodgrain and brushed.

- Can meet any design intent.

LEARN WHY PERFORMANCE, COMPLIANCE AND VALUE FOR MONEY

MAKE VITRACORE G2 THE SMARTER CHOICE

PERFORMANCE

70% MORE RESISTANT TO OIL-CANNING THAN SOLID ALUMINIUM

LIGHTWEIGHT WHICH IMPROVES HANDLING AND WORKABILITY ON SITE

EXCEEDS PERFORMANCE OF SOLID ALUMINIUM PANELS

USES HIGH QUALITY PVDF OR FEVE PAINTS KNOWN FOR THEIR EXCELLENT DURABILITY AND ARE THE ULTIMATE RESISTANCE TO WEATHER AND INDUSTRIAL POLLUTION

EASILY AND ACCURATELY INSTALLED IN A PRE-MADE CASSETTE SYSTEM

REQUIRES MINIMAL MAINTENANCE

VALUE FOR MONEY

A COST-EFFECTIVE SOLUTION GIVEN VITRACORE G2 CONTAINS OVER 40% LESS ALUMINIUM THAN SOLID PANELS

MORE EFFICIENT ON-SITE GIVEN ITS LIGHTER WEIGHT, REQUIRING LESS PEOPLE AND ANCILLARY INSTALLATION SUPPORT. FASTER TO MACHINE AND LESS CONSTRUCTION WASTE AS THE TECHNOLOGY USED IN THE CORE DELIVERS PRODUCTION EFFICIENCIES

"Vitracore G2 is not only a fully compliant and safe solution, it’s also the most cost-effective choice.”

Andrew Gillies

Managing Director, Fairview

WHY VITRACORE?

WELL...PROOF IS IN THE PERFORMANCE

ENOUGH SAID.

THE FACTS

VITRACORE G2 is now the most stringently tested product of its kind on the market, and far exceeds the performance of solid aluminium products.

VITRACORE G2 was the first bonded aluminium panel awarded the status ‘deemed non-combustible’ under the Building Code of Australia (BCA) clause C2D10(6)(G) and is fully tested as required to AS1530.1 and AS1530.3.

VITRACORE G2 is innovatively constructed from a complete aluminium structure, rather than a combustible material.

THE PATHWAY TO COMPLIANCE

We understand quality, compliance and safety are non-negotiables.

Policies, standards, and protocols are complex. We know you rely on accurate and complete data to make an informed selection.

As part of our commitment to quality and compliance, we’ve invested nearly $1M in rigorous testing. The results provide full transparency to

facilitate confident decision-making.

Full product certification includes Code Mark, fire compliance and quality assurance. Vitracore has undergone more third-party testing and verification than any other façade product in the industry.

FACT. If you want compliance proof, G2 meets and exceeds the performance criteria set out within governing codes.

VITRACORE G2 > THE CERTIFICATION TESTS

Deemed Non-Combustible by the current and 2019 Building Code Australia under clause C2D10(6)(G)

CodeMark Certified to BCA 2022 Standards

Tested to AS1530.1 & AS1530.3 by CSIRO, where it passed or satisfied both these essential tests stipulated by section C, Volume 1 of the National Construction Code

Tested to BS8414 and BR135 and successfully satisfied the requirements of both tests, which are the globally recognised standards for large-scale, cladding façade tests

International Standards – EN13501 which means G2 can be used on any building type in Europe. This was completely overseen by UL, an independent certifying body in Europe

UL Review of Manufacturing & Consistency

Landers and Rogers assessing compliance into the future

Acoustic resistant - demonstrated the sound deadening performance of Vitracore G2

Oil canning resistance

Structural performance testing – which includes bearing capacity, bending reports, cassette reports, point-load testing, and span tables – for full oversight of the physical performance properties of the product

Thermal resistance test results demonstrated the amazing performance of Vitracore G2. Tested to AS4284 for Weather proofing, where test results demonstrate that Vitracore G2 outperformed all other aluminium cladding products on the market in addition to the industry standard in air pressures

THE STRAIGHTFORWARD CHOICE

Vitracore G2 is the ideal façade cladding product for all types of construction

LIGHTER

The overall thickness of each panel is 4mm with a weight of 4.6kg/m2, compared to the average weight of a solid aluminum panel or ‘NC’ product which is approximately 8kg/m2. Vitracore G2 panels are easier and faster to install, especially useful on large infrastructure projects.

EASIER TO HANDLE

Because Vitracore is half the weight of solid aluminium and ‘NC’ alternatives, it’s easier to install and given the panels are also 50% more rigid, installers can do their jobs faster and more efficiently.

CHEAPER

Featuring over 40% less aluminium than solid panels, Vitracore G2 is a more cost-effective solution compared to solid aluminium panels. Overall construction costs are reduced when you select Vitracore G2 for your building project. Vitracore G2 is also a lightweight product which makes it easier to fabricate and install. This results in a more efficient installation process which speeds up the build process.

AVAILABLE STOCK

Our large stockholding means readily available stock and short lead times.

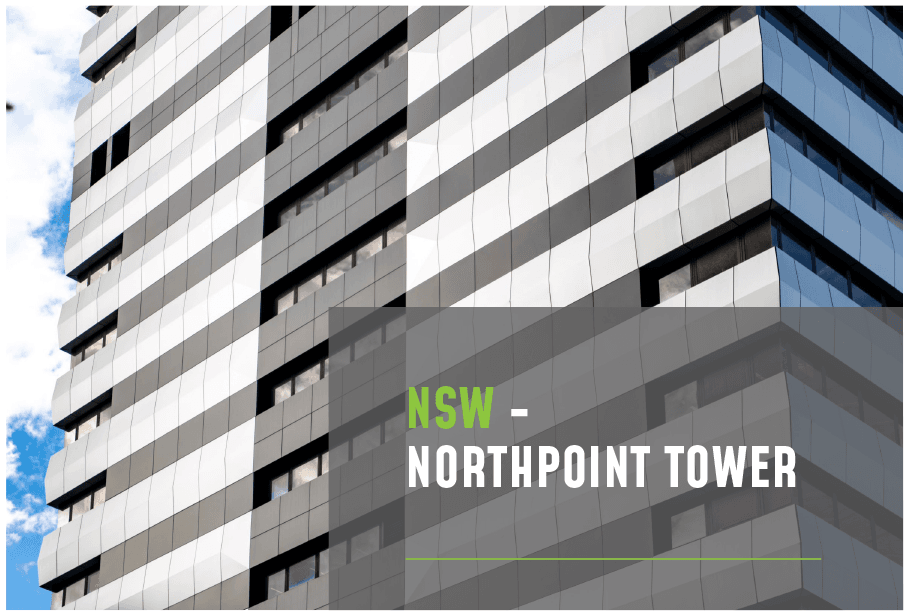

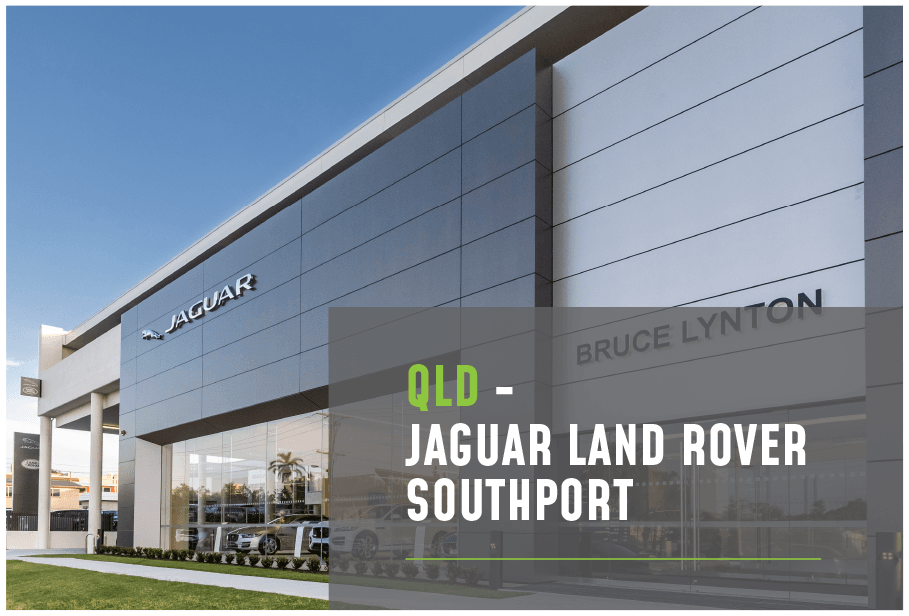

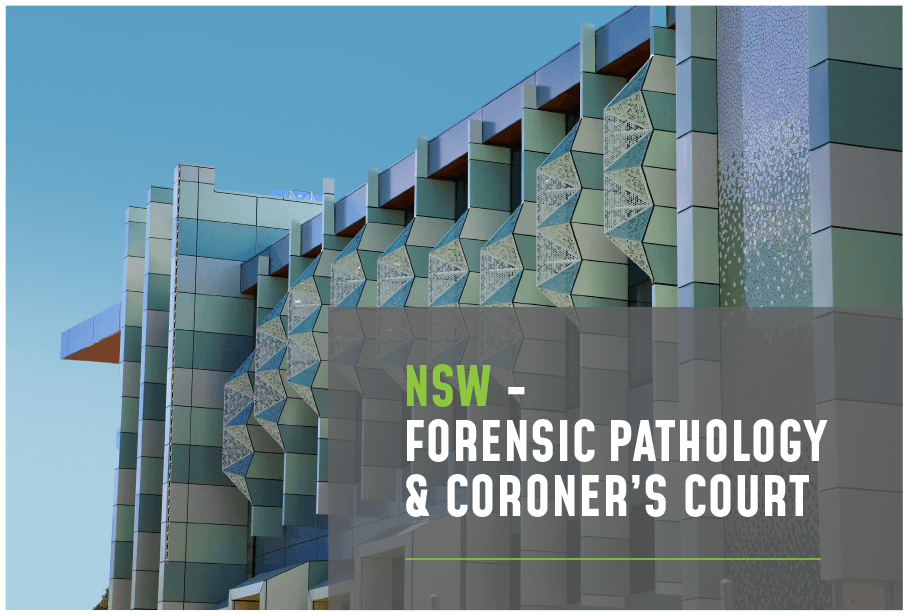

SEE VITRACORE G2 IN REAL LIFE

Vitracore G2 is suitable for application on Type A, B, and C constructions including hospitals, mixed-use developments, and residential projects. The 2022 BCA clause C2D10(6)(g) highlights the use of bonded laminated panels wherever non-combustible materials are required.

Vitracore G2 has been tested to all the standards for external façade products. In addition, we’ve completed several unique tests including Code Mark – where we hold substantial certification covering far more than any competing products. We have a lot of supporting evidence that G2 is fit-for-purpose. All compliance certifications are third-party and independently reviewed which means peace of mind for professionals who specify G2 for their projects.

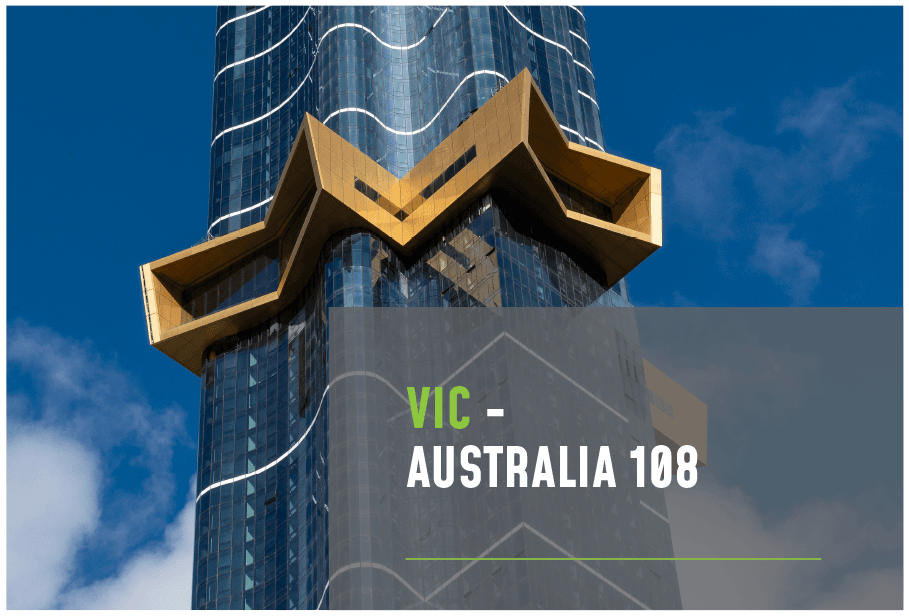

VITRACORE G2 PERFORMS AT THE HIGHEST ALTITUDE OF ANY CASSETTE SYSTEM BUILDING IN THE SOUTHERN HEMISPHERE

Australia 108 Starburst, Melbourne

VITRACORE G2

GUARANTEED QUALITY

“I recommend Vitracore G2 because the most important aspect for a business who is committed to their respected reputation, is using a product of guaranteed quality and compliance. Vitracore G2 ticks all the boxes and gets us approved.”

Harry Patras, Director of ACA Cladding

EASY FABRICATION & INSTALL

“Vitracore G2 is a preferred product due mainly to the fact it is easily fabricated and installed like traditional ACP, but is both durable and compliant, therefore providing peace of mind for both builders and installers.”

Simon Birch, Director of Birch Constructions

MY FAVOURITE & A DREAM TO INSTALL

“Vitracore G2 is by far my favourite product to work with as it's lightweight which makes it a dream to install. It's also available in larger sheet sizes. It's easy to groove and cut, which for me is the complete package. For us, all roads lead to Fairview and their products.”

Braydn Beattie, Project Manager, Black Swan Building Services

THE FAIRVIEW TEAM BEHIND VITRACORE G2 HAS OVER 30 YEARS IN THE INDUSTRY

We are committed to helping you make confident cladding choices.

We pride ourselves on the complimentary technical support we offer when it comes to navigating the current climate of the Australian construction industry, where compliance and safety of cladding products is a major focus.

We believe in building relationships and giving back to the community.

HOW WE WORK TO SUPPORT YOU AND HELP TO NAVIGATE THE COMPLEXITY

INDUSTRY COLLABORATION AND SUPPORT

We work closely with government and industry professionals to create clarity around the standards, regulations and policies related to façade cladding solutions. We will continue to dedicate significant time and resources to cladding compliance.

INNOVATIONS

AND TECHNICAL DEPARTMENT

Our in-house technical and innovations team are committed to superior performance across our complete product range. This performance is backed by research and a commitment to continuous, stringent, real-life testing of façade cladding products.

SPECIALIST FAÇADE CONSULTANTS

The single point of contact results in a deep understanding of your project requirements.

KNOWLEDGEABLE SPECIFICATION TEAM

We collaborate on your project to ensure the best design outcomes which are compliant for your client’s property developments

VITRACORE G2 IS WHERE TRUE INNOVATION MEETS INSPIRATION AND COMPLIANCE

Fairview > here to help you bring your vision to life.

With Vitracore G2, you can confidently inject creativity across many different types of architectural design and construction projects, knowing it's backed with proof of performance and compliance.

VITRACORE G2 COMES WITH A MINIMUM

15-YEAR MANUFACTURER WARRANTY.

Q |

Is Vitracore G2 compliance on class 2-9 buildings?

A |

YES. Vitracore G2 is compliant on ALL types of construction. This is independently assessed by the CSIRO and ABCB’s national codemark scheme, as well as other independent industry experts.

Q |

Was Vitracore G2 used on Grenfell and Lacrosse because it ‘got around’ AS1530.1 standards?

A |

Zero Fairview products were used in Grenfell or Lacrosse fire incidents. However, Vitracore G2 was specified as a remedial cladding for Lacrosse after an exhaustive, independent multi-disciplinary review, because it satisfies compliance requirements in a number of different ways.

Q |

Does the AS1530.1 Standard allow for any Flammable adhesive?

A |

The AS 1530.1 standard, tests products to be non-combustible. The Building Code permits a small amount of adhesive in products tested to be non-combustible, and has additional testing requirements. Vitracore G2 has less than 1% combustible content in its core, compared to many FR products which can have round 29% combustible content.

Q |

Vitracore G2 is only used in Australia because our Construction Code uses the wrong Standard to define ‘combustible’?

A |

FALSE. Vitracore G2 composition panels are used in five other countries at present. The AS 1530.1 test pass is based on the international standard ISO 1182 which is adopted in the UK, USA and Europe. Plus, Vitracore G2 also can be compliant in a second way; ie, as part of a performance solution.

Q |

Should we be using the ‘A2’ European Standard (EN13501.1) not AS1530.1?

A |

JUST AN OPINION. There have been no building fires spread by products deemed non-combustible to AS 1530.1, which is a very tough test standard. EN1350.1 actually includes the European version of AS 1530.1 (namely EN ISO 1182). Vitracore G2 achieves A2 status when tested to EN 1350.1 and by that measure is compliant on high rise construction in both Europe and the UK.

Q |

Does Vitracore G2 meet the National Construction Code when tested as an “assembled panel”?

A |

YES. Vitracore G2 has been independently assessed as compliant across several test formats deemed suitable to the National Construction Code. Note, G2 performs better in large-scale tests than most FR or A2 panels do.

Q |

Is Vitracore G2 banned in QLD?

A |

NO. Vitracore G2 is permitted for use in all states and territories of Australia.

Q |

Vitracore G2 is unsafe and should be removed from buildings?

A |

In lab or real-life style tests, Vitracore G2 has been independently assessed as compliant across several test formats deemed suitable to the National Construction Code. Note, G2 performs better in full-scale tests than most FR or A2 panels do. G2 has never been involved in any serious or fatal incident and, in the real world, inhibits fire. Read our case study.

Q |

What independent testing of Vitracore G2 has been done?

A |

The CSIRO has tested G2 using samples independently supplied by Underwriters Laboratories. Codemark. The British Board of Agrement has recently issued independent certification to Vitracore G2’s compliance in the UK. Leading fire engineers have reviewed and rubber-stamped the product's compliance and conformity. NOTE: rigged-to-perform-poorly testing of Vitracore has just been outed (Dec2020) by the Grenfell Inquiry.

Q |

Vitracore G2 performed poorly in the Exova test in Dubai?

A |

Grenfell Inquiry questioning (09/12/20) of Kingspan executives has confirmed that the Exova large-scale testing of a wall façade featuring Rockwool Insulation and Vitracore G2 in Dubai was deliberately pre-engineered to fail and generate maximum flame.

Q |

Vitracore G2 is a highly flammable product?

A |

G2 was the first bonded aluminium panel to be awarded the status ‘deemed-non-combustible‘ under the Building Code of Australia (BCA) under Clause C1.9e(vi) and is tested to AS1530.1 and AS1530.3. To provide further peace of mind and demonstrate full scale performance Vitracore G2 has also been large scale tested to the requirements of AS5113 and BS8414, and did not propagate flame.

Q |

Vitracore G2 is easily damaged by hail?

A |

There are a limited number of Vitracore G2 projects which have faced hail damage; they also saw significant hail damage to other materials considered to be acceptable such as steel roofing. In these cases, only the panels installed horizontally were ever damaged. Vitracore G2 passed the FM 4473 Test, which proves the products ability to perform under impact, in such cases as hail storms.

Q |

Vitracore G2 is a cheap Chinese product?

A |

Fairview has earned its reputation as a supplier of quality products. A dedication to the total fulfilment of our client’s and customer’s expectations is reflected by a complete quality control system, beginning at the point of specification and continuing through to delivery of the guaranteed products.

Q |

Vitracore G2 fails at weatherproofing?

A |

Fairview cladding products are Australian Standards AS4284 tested for high performance; energy efficiency and minimal maintenance. Vitracore G2 has been tested on two substrates to AS 4284 with great results. This is also addressed in our Codemark Certificate.

Q |

Vitracore G2 sales are rapidly decreasing?

A |

Fairview has sold more than one million square metres of Vitracore G2. Vitracore G2 is the proven choice for use where deemed non-combustible cladding must be specified such as hospitals, schools and high-rise buildings.

Q |

Fairview refuses to provide the requested test reports to builders, installers & architects?

A |

Fariview has invested over $800,000 into diverse and stringent testing of Vitracore G2 – we’re serious about this product and we are 100% confident in the product’s credibility. All product assessments stipulating compliance for deemed non-combustible products are publicly available for review.

Q |

The Victorian Building Authority has prohibited the use of Vitracore G2?

A |

The Victorian Building Authority’s current view in relation to Clause C1.9(e)(vii) of the BCA, is that an adhesive layer incorporated in bonded laminate materials, is not required to be tested under Australian Standard AS 1530.1-1994: ‘Methods for fire tests on building materials, components and structures’, provided that each adhesive layer does not exceed 1 mm in thickness and the total thickness of the adhesive layers does not exceed 2 mm.

Q |

Vitracore G2 has only passed the technical basis only test in order to be marketed as ‘non-combustible‘

A |

No pre-finishes or coated product on the market has met the AS 1530.1 criteria as a complete product – the AS 1530.1 doesn’t allow for testing of the finished product; rather each individual component needs to be tested per the standard. Whilst Vitracore G2 is Deemed To Satisfy, it has also proven its large scale performance by avoiding spread of fire on two building fires which occurred in Australia.

Q |

The Vitracore G2 cladding on many high rise buildings in Melbourne is having to be replaced due to non-compliance?

A |

Vitracore G2 has not been removed from any buildings in Melbourne. Vitracore G2 aluminium cladding has undergone the most demanding and stringent levels of testing stipulated, and it remains among the safest and most certified, complaint cladding products you can choose.

Q |

Vitracore G2 has a chimney effect?

A |

Vitracore G2 has never been involved in the ignition, fuelling or spreading of any facade fire incident anywhere. That’s because it’s not-combustible-material-core has zero polyethylene or other significant fuel load – it only has profiled aluminium layers and adhesive, comparable in thickness to most surface coatings – large scale testing has proven this point.

Q |

The Bonded Laminates Clause is being removed from the National Construction Code?

A |

The Australian Building Codes Board has reviewed the bonded laminates clause in detail, in the first instance asking industry for reasons it should be removed and the second, asking industry for reasons it should remain. Even after this, with no factual evidence presented as to products under this clause being cause for concern, it would be incredibly unlikely this will be reviewed again. Regardless, Vitracore G2 can demonstrably meet the performance requirements of the building code for compliance.