Learn how to execute a sustainable and compliant cladding rectification project.

DOWNLOAD E-BOOK

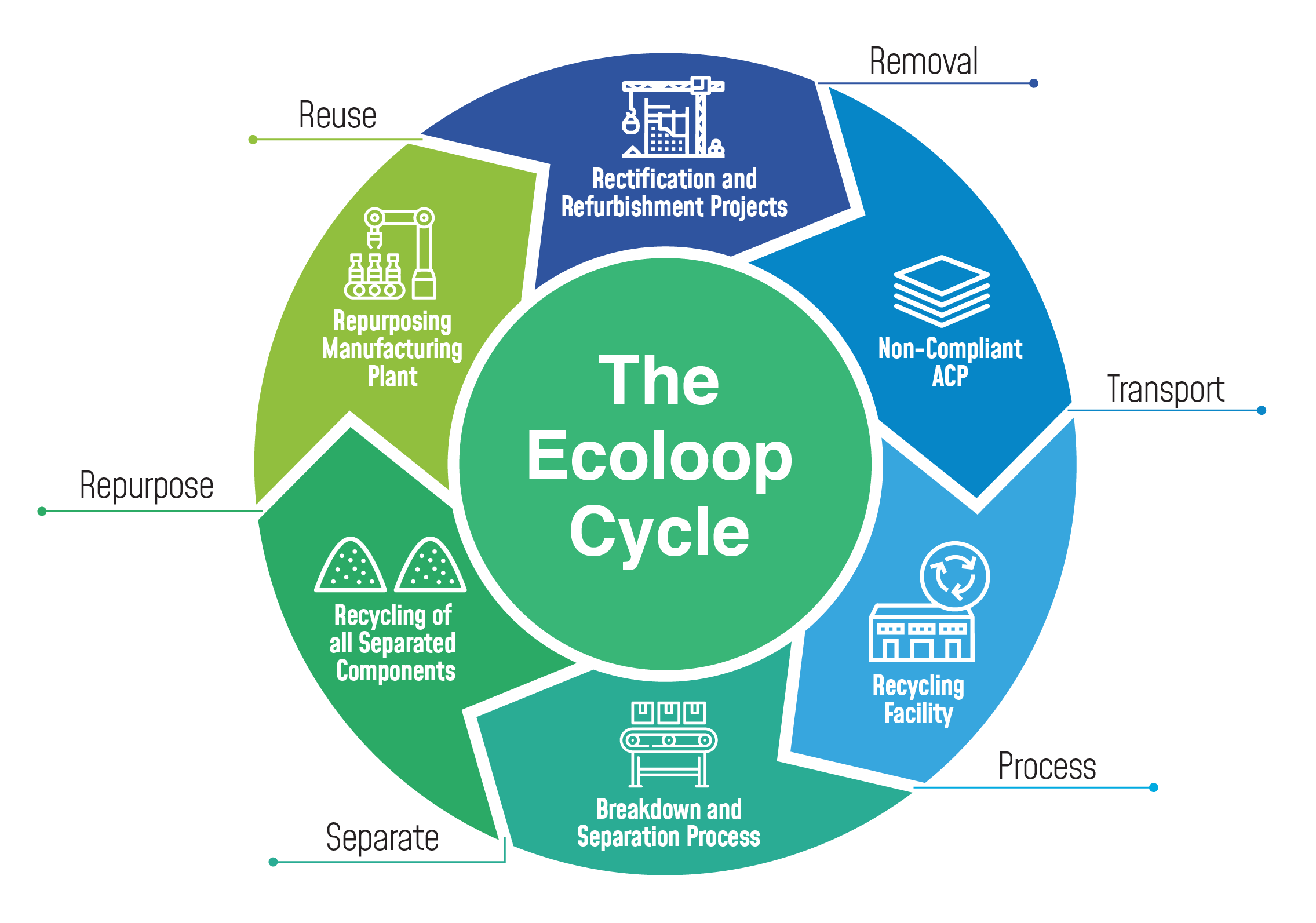

The Ecoloop Solution

Ecoloop is Australia’s first Aluminium Composite Panel (ACP) recycling solution for non-compliant cladding waste. Our proprietary Ecoloop solution reduces the environmental impact of cladding rectification work, diverting 100% of non-compliant cladding waste from landfill while reducing greenhouse gas emissions and natural resource consumption.

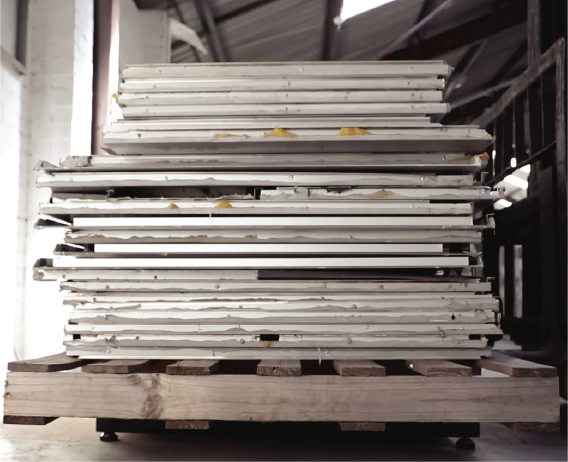

A Cladding Crisis Can Cause an Environmental Disaster

As part of the the State Government's mandated removal of polyethylene (PE) and fire retardant (FR) cladding from buildings across Australia, an estimated 4.2sqm is pegged for removal. Ecoloop is the solution to recycle and repurpose that cladding waste, otherwise set for landfill.

ACP cladding is not only non-compliant, inefficient and unsustainable, but dangerous. Removing potentially flammable cladding shouldn’t just be a matter of compliance, but of conscience. We’re here to help you fulfill your ethical obligations in a way that doesn’t cost the Earth.

Why Ecoloop?

Our unique and sustainable separation process is performed onsite at Australia’s first ACP recycling facility for reclassing waste.

Our proprietary Ecoloop separation process ensures all components of ACP cladding waste - from the aluminium, PE/FR cores, to the screws, top hats and even paints and sealants - are diverted from landfill through recycling and repurposing.

But don’t take our word for it, the stats speak for themselves:

4.2M m2

of non-compliant cladding is estimated to require replacement in Australia.

100%

of material collected by Ecoloop is diverted from landfill.

420K

tonnes of greenhouse gases saved by ACP cladding waste recycling.

16.8M

trees over a year is the equivalent CO2 reduction from diverting cladding waste from landfill into Ecoloop recycling.

1%

is the cost of recycling ACP out of total recladding costs.

Simplicity

We can supply the compliant replacement cladding for your project, and collect the non-compliant waste, which is then recycled and repurposed via Ecoloop.

Sustainability

100% of non-compliant ACP cladding is diverted from landfill. Even the non-recyclables such as paints and sealants find new life as a coal offset called Process Engineered Fuels.

Compliance

We have a range of stringently-tested, compliant and quality cladding solutions that can be colour-matched to suit your needs.

Playing Our Part to Contribute to the Circular Economy

When it comes to greenhouse gas emissions, every 1m2 of non-compliant ACP cladding that we recycle reduces emissions to the equivalent of CO2 reduction as four trees per year. With an estimated 4.2 million square metres of non-compliant cladding in need of replacing in Australia alone, that’s the potential equivalent of planting a super-forest of over 16.8 million trees!

3 Easy Steps to a Successful

Cladding Rectification Project

Useful Resources

Ecoloop is Your Trusted Cladding Compliance Partner

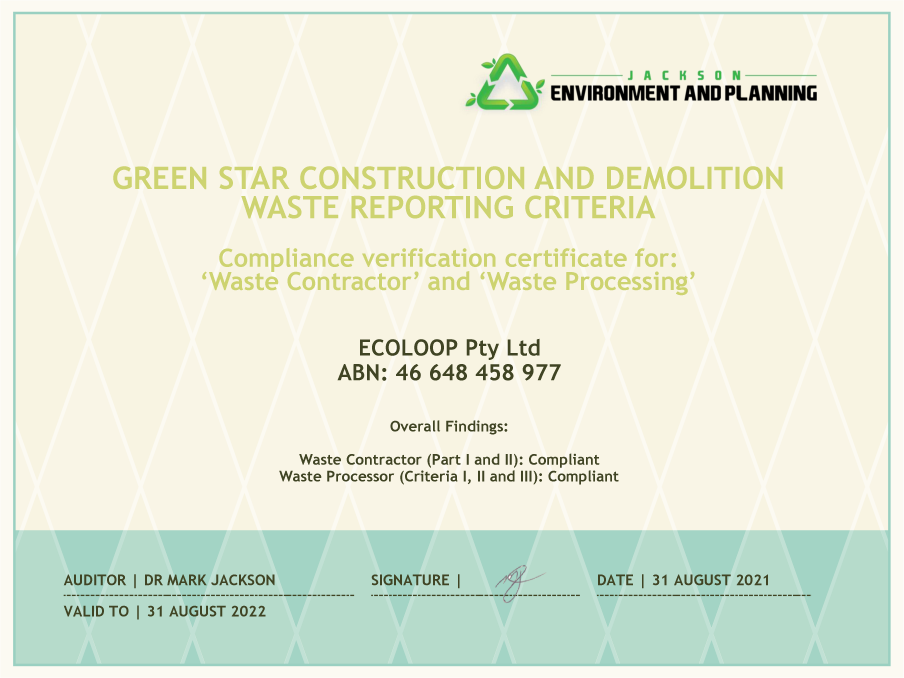

Are you Green Star Compliant?

Green Star is Australia’s largest voluntary and only truly holistic sustainability rating system for the design, construction and performance of buildings, fit outs and communities.

Green Star provides a common language to describe how to achieve world-leading benchmarks for sustainability across a wide range of categories.

A Green Star certification aims to transform the built environment by providing independent assurance that particular benchmarks across a range of categories have been met to an agreed standard.

Frequently Asked Questions

Can you provide an example report template for the process?

Absolutely. Click on the Get in touch button and one of our team will send an example to you.

How long has Ecoloop been in operation?

The Ecoloop facility has been fully operational since 11 January 2021.

Is Ecoloop approved to operate?

Ecoloop was approved to operate by Lithgow Council in December 2020.

Are site tours available?

Yes. Click on the Get in touch button and we will organise a tour date with you.

What is the estimated timeline for throughput of material?

The estimated timeline for throughput of the material (the whole recycling process) differs for the aluminium and PE. Timeline also varies dependent on the particular product the material is turned into; however, it ranges from 4-6 weeks for the aluminium and 6-10 weeks for the PE.

What is the process?

Cladding is removed from rectification and refurbishment projects across Australia, stacked and backloaded onto one of Fairview’s trucks which makes its way back to the Ecoloop facility. This backload service helps to minimise carbon footprint. Upon arrival, panels are accurately weighed and recorded before entering the primary shred of all components. Once in manageable sizes, the material enters the Ecoloop process which separates the material into the different components (largely aluminium, PE/FR core, mixed residuals and ferrous metals). Once separated, the materials are bagged and distributed for repurposing.

What are the separated materials repurposed into?

Aluminium is sent to an aluminium smelter to be made into new aluminium products, such as window frames, park benches and building products. Polyethylene is sent to a plastic manufacturer to be repurposed into new and safe plastic products, such as concrete bar chairs, flower pots, commercial landscape drains and pits, piping, plastic pallets and bottles. Ferrous metals go to a metal recycler for the reproduction of new metal products. Mixed residuals – unlike any other ACP recycling process, Ecoloop diverts any remaining non-recyclable fractions into the Waste to energy process which in turn is used to offset the use of coal. Uniquely, the Ecoloop solution prevents any of the elements from ending up in landfill.

How does Ecoloop differ from other recycling options?

Unlike any other ACP recycling process, Ecoloop is a holistic solution designed to manage ALL components from rectification waste. The process diverts any remaining non-recyclable fractions into the Waste to energy process which in turn is used to offset the use of coal. Ecoloop is also a bespoke service, tailored to individual projects needs to achieve our client’s sustainability targets.

What is the pricing structure?

Ecoloop is priced competitively to landfill, enabling customers to make the sustainable choice. There is a three-tiered pricing structure available dependent on what your sustainability/recycling objectives are.

Do we accept other materials beyond PE?

Absolutely. In addition to PE, we accept and process FR along with Zinc and Copper skins. For other material, we are happy to review.

Is this service available to all States?

The Ecoloop service is available for all rectification and refurbishment projects across Australia.

Facade Rectification, Replacement and Recladding Gallery

What Our Clients Say

“After witnessing the fully functioning Ecoloop process and watching aluminium and polyethylene being completely separated, I am confident to now recommend this recycling initiative to the market.”

Project Manager | Shape Australia

“Fairview were a pleasure to work with and clearly have a passion for everything they do. The team are highly knowledgeable, responsive and happy to assist us at every opportunity. Fairview would be our first point of contact for any project involving aluminium façade panels.”

Director | Sissons Architects

“For over a decade, Fairview and Casello have been in partnership; with a strong working relationship with all levels of employees. This strong rapport enables us to be able to call staff when required and deal with any challenges immediately. A relationship like this is hard to come by and is why we choose Fairview time and time again.”

Procurement Manager | Casello

“The market is now full of clients looking for sustainable options. We often get asked how the materials are recycled, so we can now confidently specify a solution which is Australian, traceable and transparent.”

Business Development Manager | Casello

“I’m very impressed by the Fairview Warehouse and Ecoloop facility. It’s a great initiative that addresses a huge gap in the rectification market, finding a solution to the excessive cladding waste. Ecoloop closes the loop between supplier, installer and fabricator. It’s a good asset for them to have!”

Director | Aesthetic Building & Façades